Mechanical seal definition

Mechanical seal is a device used to solve the sealing between rotating shaft and engine body. The device is composed of at least one pair of end faces perpendicular to the rotating shaft, which are kept stuck and relatively sliding under the cooperation of fluid pressure, elastic force (or magnetic force) of compensation mechanism and auxiliary seal to prevent fluid leakage.

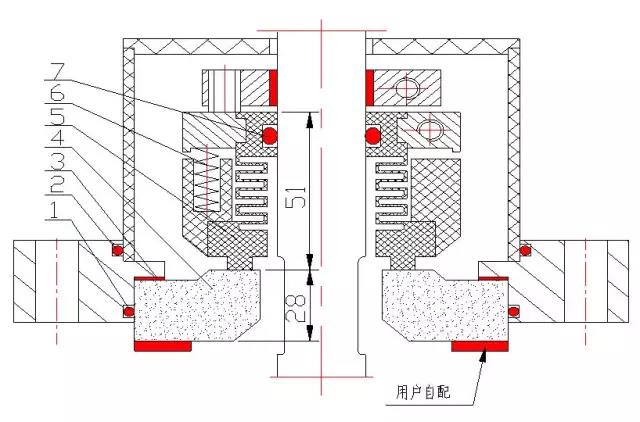

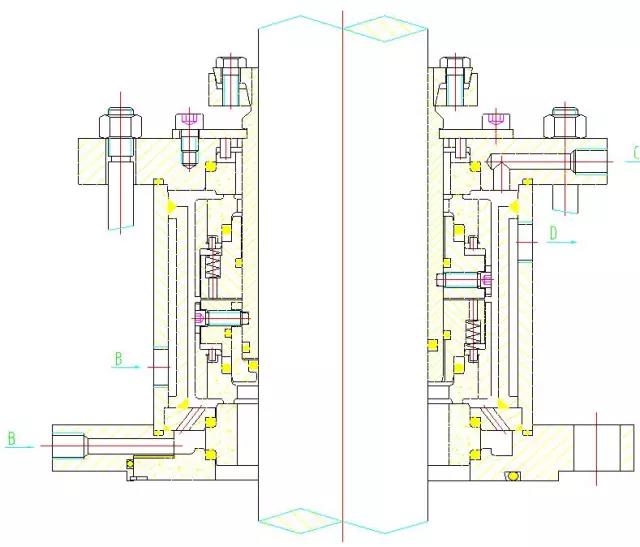

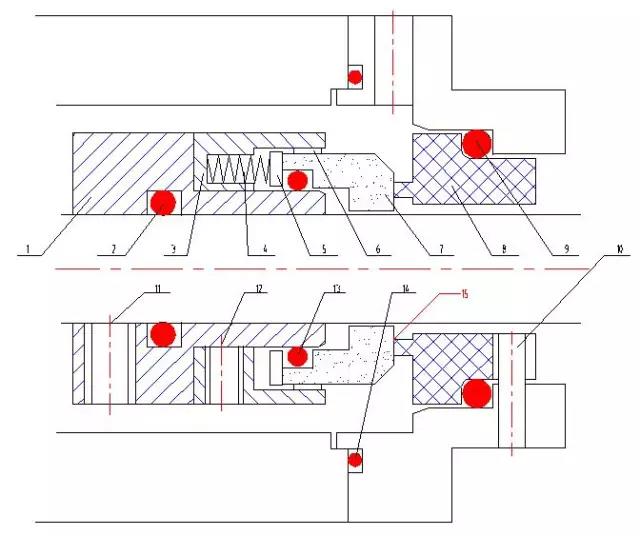

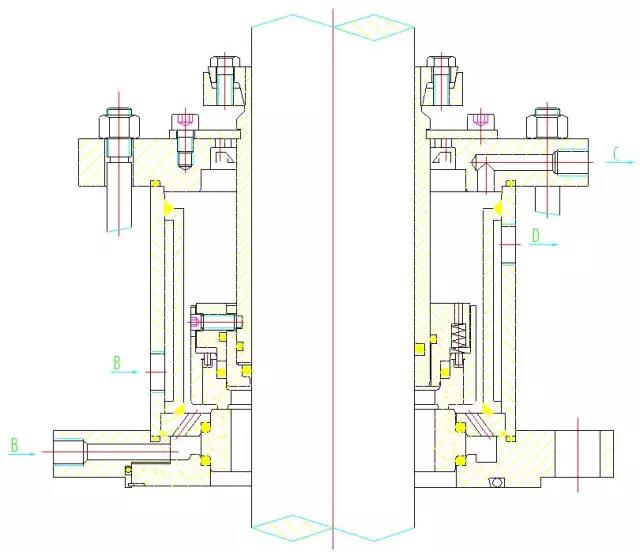

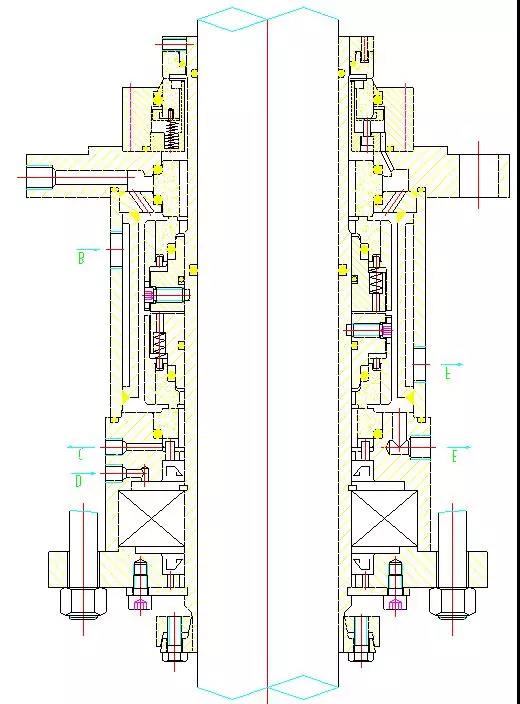

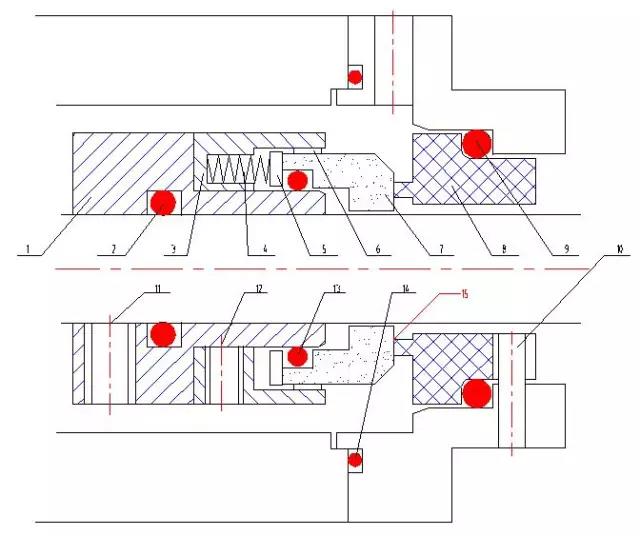

1. Drive ring; 2. Seal ring 1 (leakage point 1);

3. Spring seat; 4. Spring;

5. Push ring; 6. Drive pin;

7. Moving ring; 8. Static ring;

9. Sealing ring (leakage point 2); 10. Anti rotation;

11. Set screw; 12. Set screw;

13. Seal ring 3 (leakage point 3); 14. Seal ring 4 (leakage point 4);

15 Leakage point 5

Basis for selection of mechanical seal

Medium: (determine material and structure)

Pressure: (determine the structure type and material)

Temperature: (determine the structure type and material)

Speed: (determine the structure type and material)

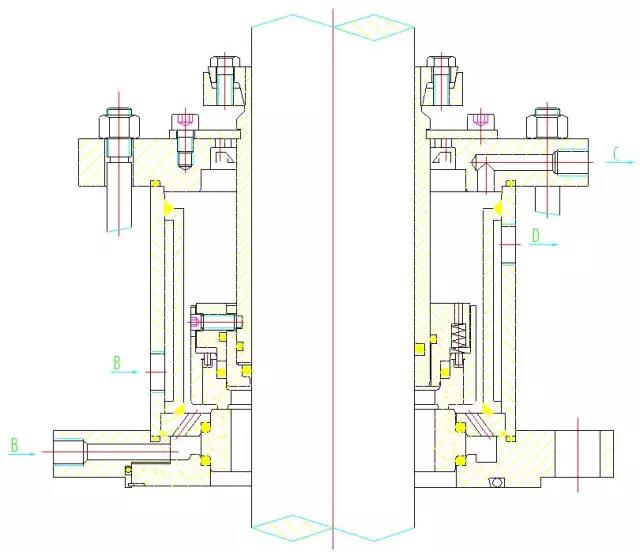

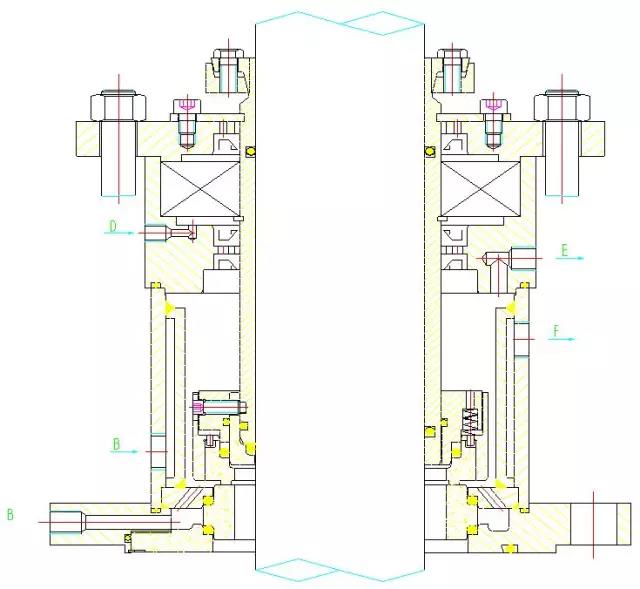

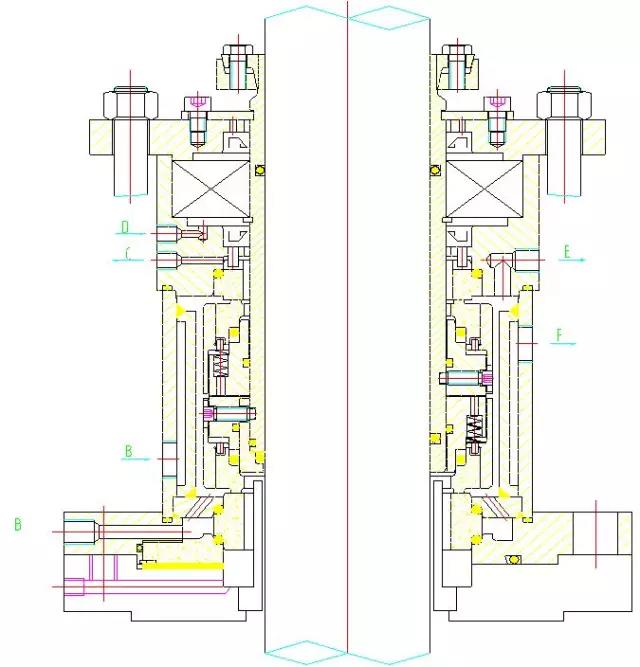

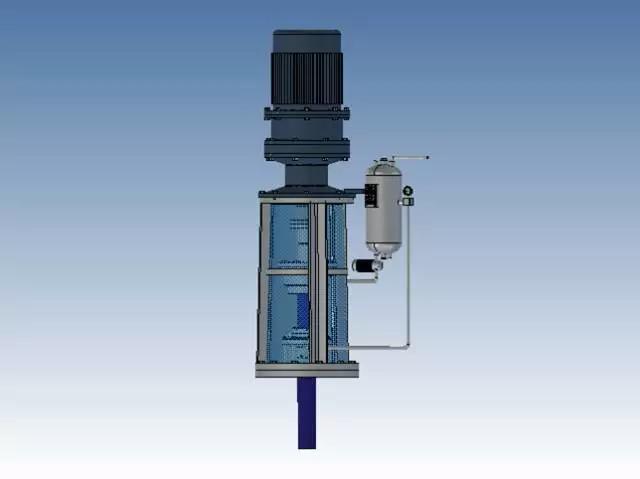

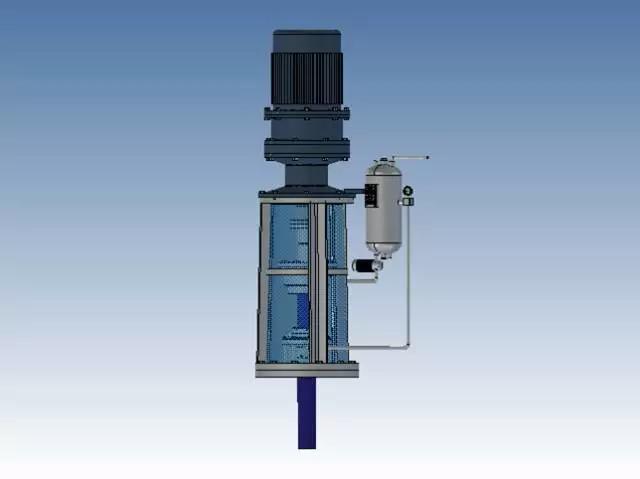

Complete system diagram of kettle mechanical seal

Precautions for installation of kettle mechanical seal

After the installation of the vertical vessel, first align the vessel mouth horizontally and ensure that the foundation is stable;

Before installing the mechanical seal, check the radial runout of the mixing shaft at the seal part: the steel reactor is less than 「 d/100mm; the radial runout of the glass lined reactor is less than 「 d/30mm; the axial runout of the mixing shaft is less than 0.5mm;

The tolerance of mixing shaft is h8 (glass lined mixing is h9), and the surface roughness is ≤ 1.6 μ M (subject to the latest standard)

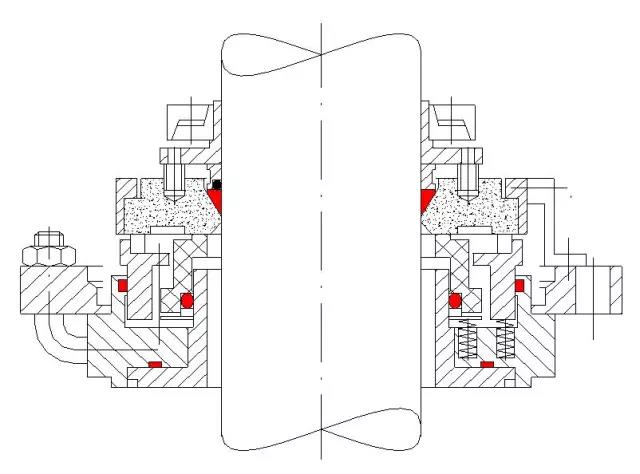

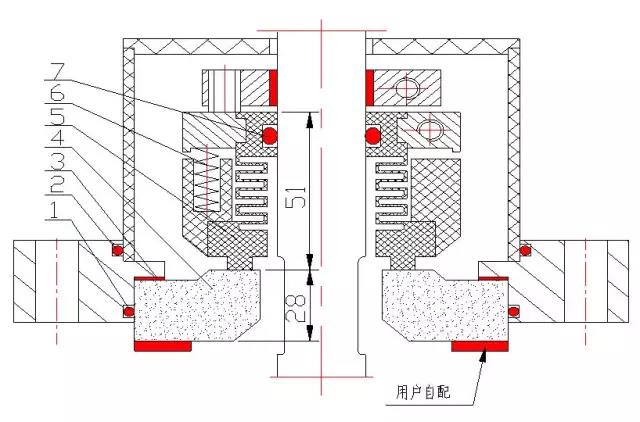

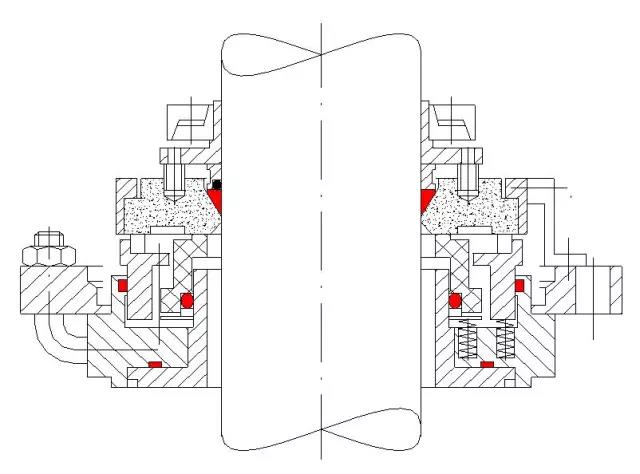

Before the mechanical seal is installed on the kettle body, the transition chamfer of the mixing shaft end must be checked: generally 3 × 20 ° and smooth transition. The left figure is for domestic use, and the right figure is for German standards.

Non cartridge single end mechanical seal shall be installed step by step according to the steps in the instruction manual;

The double end mechanical seal shall be subject to static pressure test first, and the test pressure shall be the design pressure. The test medium shall be oil or water, and the average leakage shall be less than 5ml/h after pressure holding for 30min, so it is determined that it can be installed;

Apply a small amount of grease on the outside of the shaft or shaft sleeve where the mechanical seal is installed, install the mechanical seal on the mixing shaft, properly pull out the shaft for about 50mm, and wipe the grease out of the locking chuck;

Install the frame, coupling, motor reducer and other transmission parts in order, and confirm that the matching and positioning meet the design standards;

Then lock the set screw connecting the lower part of the mechanical seal with the kettle mouth, (if the gasket has a locking force standard, use a special tool to meet the requirements) fix the locking chuck on the upper part of the mechanical seal, and finally remove it Cartridge mechanical seal Upper positioning card;

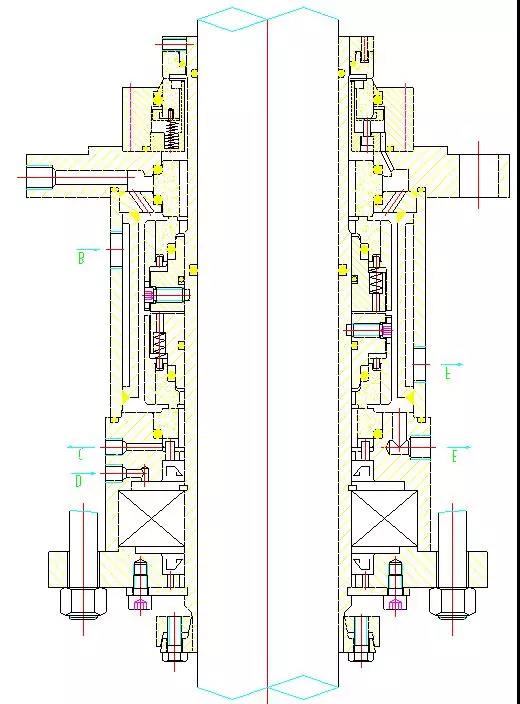

Diagram of transmission device after assembly

For mechanical seals without auxiliary devices, open the sealing liquid port and fill it with sealing liquid before plugging it. (The sealing liquid is usually clean glycerin, engine oil, pure water, etc.) If the sealing liquid is used for ordering, there should be specific requirements, and it can only be used when the design has considered the influence of the medium;

Operating pressure without auxiliary device ≤ 0.3MPa (except for bidirectional balanced mechanical seal); In addition, it is necessary to fill the mechanical seal with sealing fluid regularly. The filling of sealing fluid should be carried out under the condition of shutdown and no pressure in the kettle.

If there are auxiliary devices, connect the pipelines between all mechanical seals and auxiliary devices according to the pipeline connection diagram;

Fill the mechanical seal and auxiliary device with sealing fluid and exhaust the air. The service pressure with auxiliary device can reach the maximum pressure when the mechanical seal is designed;

The pressure of the auxiliary device of mechanical seal is generally 0.1MPa higher than the pressure in the kettle. Considering the pressure fluctuation of hydraulic pump station, the minimum pressure should be 0.1MPa higher than the maximum pressure in the kettle;

During the use of mechanical seal, when the sealing fluid is lower than the minimum warning line of auxiliary device, the sealing fluid must be supplemented for mechanical seal in time;

For medium with crystallization condition, regularly check whether the pipeline of the auxiliary system is unblocked, and ensure that all cooling water of the system is unblocked every time under high temperature condition;

Dry grinding is prohibited for mechanical seals without dry grinding design;

Under strong corrosion conditions, it is recommended that the sealing fluid can be completely replaced when the machine is shut down after being used for about one month, so as to ensure that the operating environment of the mechanical seal is in good condition and ensure the longest service life.

If the impeller of mixing shaft is not calibrated for dynamic balance, start mixing when there must be 2/3 kettle of materials or water in the kettle. Dynamic pressure test is not allowed when the kettle is filled with water;

The static pressure test on the kettle is 1.25 times of the actual service pressure, and the dynamic pressure test is the actual service pressure;

The leakage of mixing shaft diameter ≤ 80mm is less than 5ml/h, and the leakage of mixing shaft diameter > 80mm is less than 8ml/h (special designed seals are not subject to this limit).

The mechanical seal is not allowed to be installed on the container and transported to the user factory without safeguard measures;

The mixing shaft without dynamic balance calibration shall not be operated in the empty kettle state;

Turn on the cooling water before each use, and turn off the cooling water after each use;

If the mechanical seal transmission has a directional design, it shall be confirmed that it conforms to the designed rotation direction before operation;

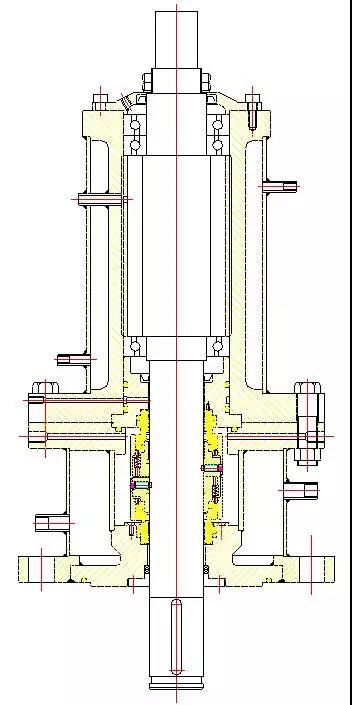

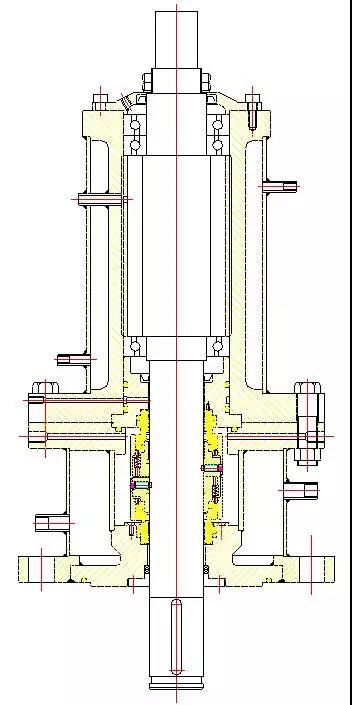

Analysis of typical structure of mechanical seal for kettle

Single end non container type

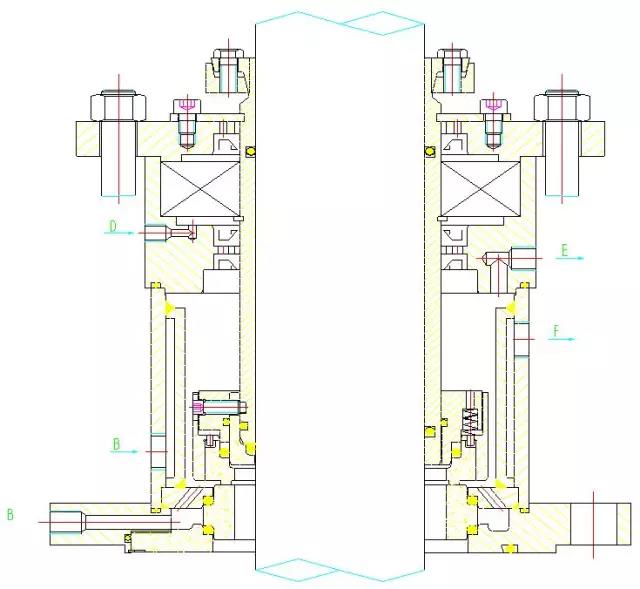

Single end container type

Single end surface cylinder type with bearing

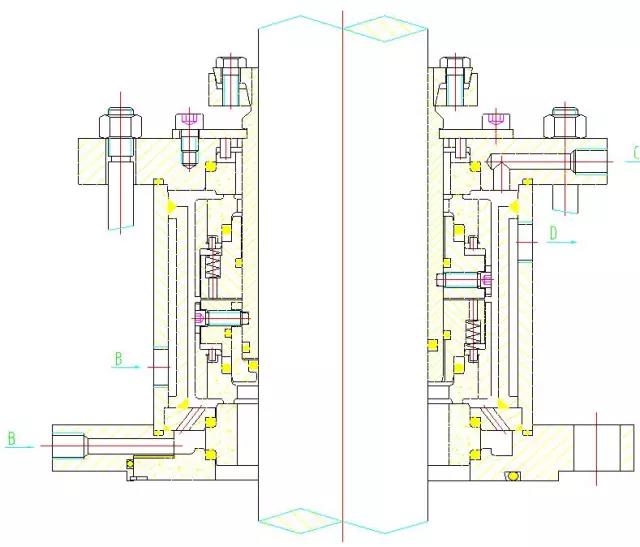

Double end cylinder type

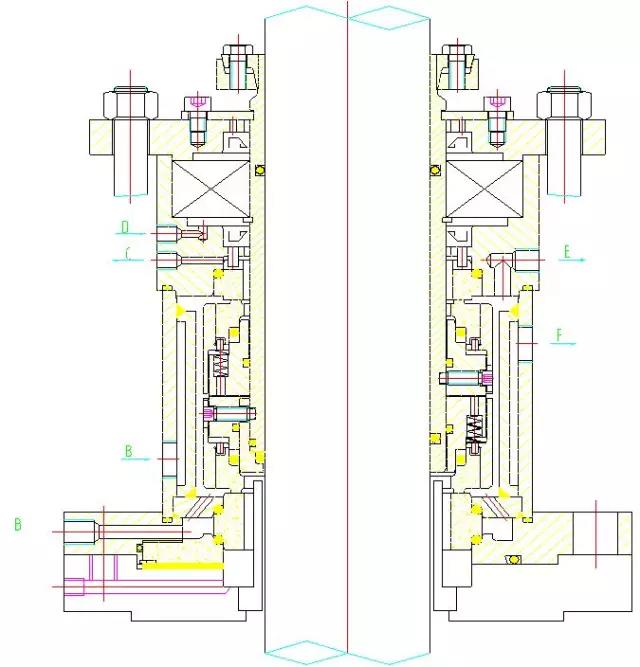

Double end bearing cartridge type

Radial double end face

Bottom entry side entry container type

Integrated container type with short shaft

Single end surface typical structure