Mechanical seal for kettle What are the characteristics of? What are the causes of wear?

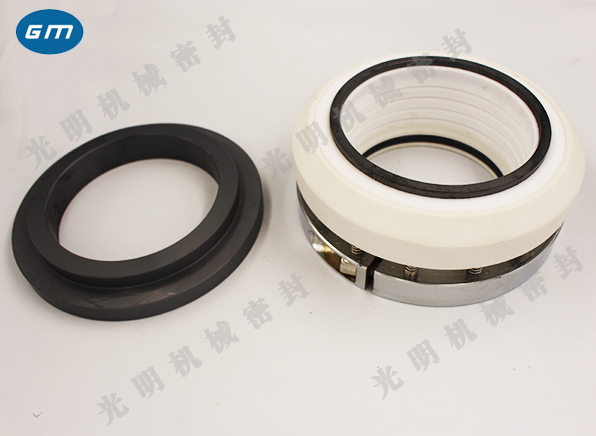

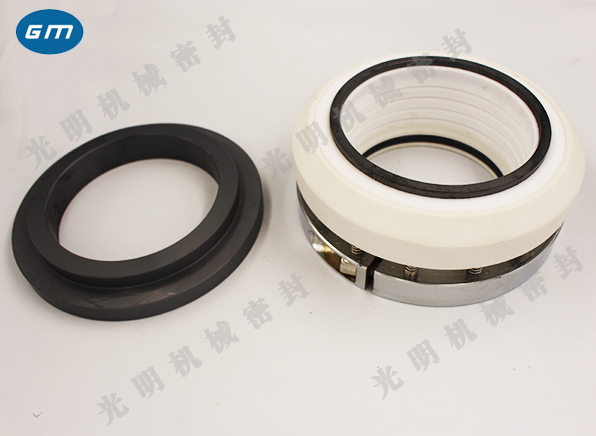

The mechanical seal is a device that is formed by at least one pair perpendicular to the end face of the rotating axis, by the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism, and by the cooperation of the auxiliary seal, so as to keep the relative sliding when sticking together and prevent the fluid from being exposed. The auxiliary seal of the compensation ring of the mechanical seal is metal bellows, which can also be called bellows mechanical seal.

The mechanical seal can be divided into internal and external type according to the installation position of the head; According to the structure and arrangement of elastic elements, mechanical seals can be divided into multiple springs, diaphragms, single springs, bellows, etc; Mechanical seal can be divided into single end face and double end face according to the number of sealing faces and sealing heads; Mechanical seals can be divided into balanced type and unbalanced type according to the pressure unloading degree of the medium acting on the seal face.

Mechanical seal is a device for axial end face sealing mainly by preloading static and dynamic ring end face sealing pairs with elastic elements, compressing medium pressure and elastic element pressure. Generally, mechanical seal is divided into two categories: contact type and non-contact type. The mechanical seal has the characteristics of limited leakage, high sealing pressure, long service life, good vibration resistance, no adjustment during operation (with spring and fluid pressure) and complex structure, inconvenient disassembly and assembly.

Mechanical seals are easy to wear in five aspects: the first is erosion (brush) wear: due to the high-speed flow of liquid or gas and erosion; The second is abrasion wear: this kind of wear is very easy to occur when the gap temperature is high due to chemical corrosion. The third is adhesive wear, which is caused by the mutual attraction between the surface forces of two sliding friction pairs. The fourth is abrasive wear: it is caused by grinding of two rough surfaces or foreign matters in the sealing gap being used as abrasive. The fifth is surface fatigue wear: caused by fatigue cracks and thermal stress cracks on the sliding surface.