Mechanical seal for kettle What are the structural characteristics of? In terms of sealing principle, the machinery used for kettle and discharge chute is the same as that used for pump, but its pump mechanical seals have the same operating conditions and operating technology. Therefore, the requirements for seal structure design and sealing system are different from those for pump mechanical seals, and have their own characteristics:

1. Large radial vibration and axial displacement of mixing shaft

The rotating shafts of kettle and discharge chute are vertical structures with large shaft diameters, respectively Φ 178 and Φ 120mm, and the mechanical seal arm for the suspended kettle is long. When mixing, the eddy current produced by the material will not only move horizontally, but also have a circulation activity in the up and down directions, thus causing radial vibration of the mixing shaft. In addition, the axial thrust caused by mixing, the mechanical seal used for the dead weight pump of the mixing shaft and the axial load of the material pressure together lead to axial displacement. These unlucky factors easily lead to poor fitting of the seal end face, unstable liquid film, and sometimes crack the soft sealing environment, resulting in the failure of the reactor mechanical seal.

2. Gas phase seal

Most of the sealed media used for the mechanical seal of kettle and discharge chute are gas rather than liquid. Because the materials in the kettle are not always full of kettle, they are liquid only when the materials are full of kettle, so the sealing conditions during operation are harsh, and the sealing end face is often in the condition of gas interference, which aggravates the wear of the sealing end face.

3. Off design operation

The material undergoes chemical reaction in the kettle. The process is that the temperature and pressure are reduced from high temperature and high pressure to normal temperature and pressure; When new materials enter the kettle, the temperature and pressure in the kettle return to high temperature and high pressure from the beginning. Repeated replacement and change of pressure and temperature will bring bad luck to the seal, which is easy to cause hydraulic deformation and thermal deformation of the mechanical seal end face, resulting in leakage of the seal end face. Together, repeated changes in temperature and pressure are also likely to accelerate the aging and deformation of the auxiliary seal ring, leading to seal failure.

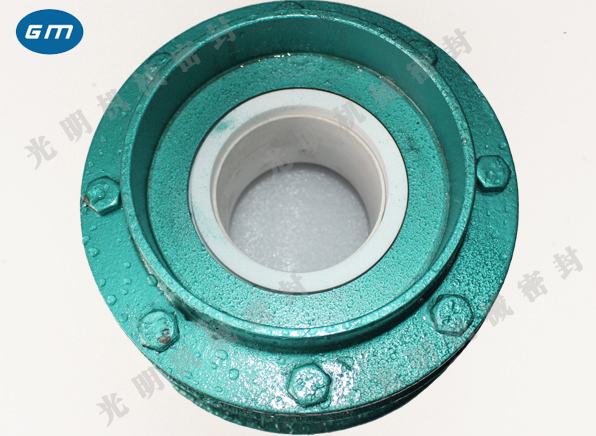

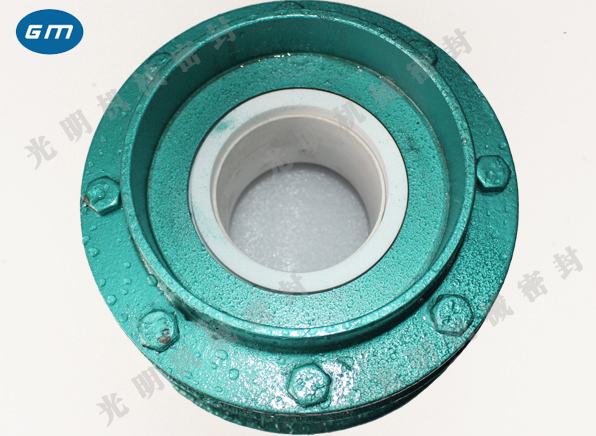

4. The seal shall be easy to assemble and disassemble

The reaction kettle is generally vertical equipment, and its installation method is: electric reducer rack reaction kettle. The mechanical seal is between the cauldron flange and the coupling of the rack, so that the mechanical seal can be extracted from the axial neutral gear between the two shafts when it is replaced. The mechanical seal for the kettle is container type, which is assembled with flange, shaft sleeve, stub shaft and mechanical seal. It can be repaired separately outside the kettle and replaced directly, so it is easy to assemble and disassemble. There is no neutral gear between the discharge chute shaft and the transmission shaft, and the mechanical seal is directly installed on the shaft. There are two push bearing supports on the upper end of the seal. During assembly and disassembly, the motor and frame should be removed, and then the mechanical seal should be installed. Because the equipment is bulky, it needs to be lifted before it can be carried out. It takes time and labor to assemble and disassemble the mechanical seal.