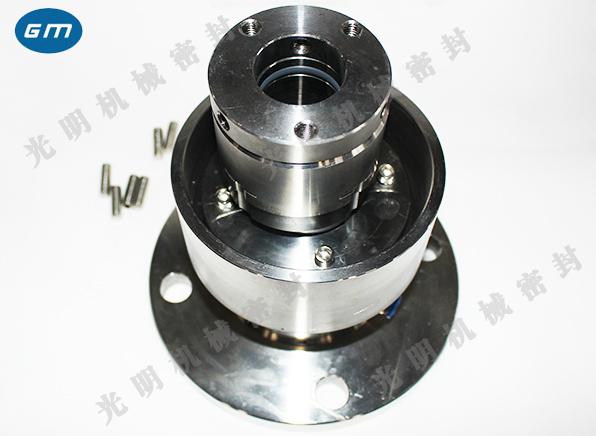

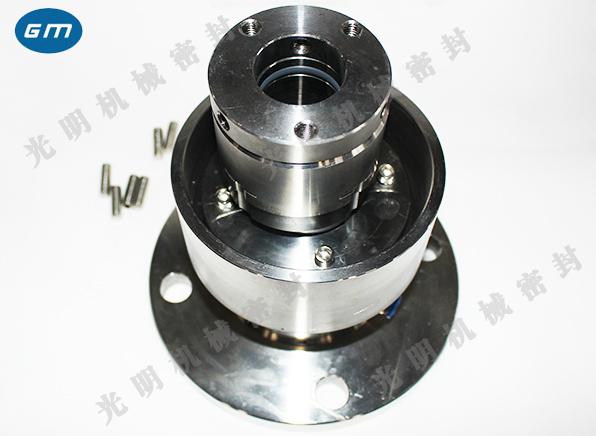

Mechanical seal for kettle The manufacturer introduces the flushing scheme

Requirements for mechanical seals

It is generally divided into two parts: liquid seal (this issue focuses on analysis) and gas seal (that is, dry gas seal, which will be summarized and pushed to everyone later)

Liquid seal is a mechanical seal specially designed for sealing liquid. In fact, the liquid film between seal faces is very small - equivalent to 20 parts per million or half a micron. This film helps isolate and lubricate the seal face. When considering the pressure, temperature and speed that the seal can withstand, we will understand that this is an incredible technical achievement. This is only possible if we have a high-quality liquid membrane.

How to become a high-quality liquid membrane?

1. The liquid must be stable and not collapse under operating conditions

2. The liquid must be a lubricant with good performance

3. The liquid must be kept liquid in the sealing chamber and will not flash or evaporate

4. The liquid should be clean and free of pollutants or solid particles

5. The liquid shall have the purpose of flushing scheme of medium viscosity mechanical seal

Direct injection of liquid into the high-pressure side of double or single seal is called "flushing". Generally, pumps shall be flushed, especially light hydrocarbon pumps.

1. Flush to dissipate heat. The heat generated by the liquid seal must be controlled. This can be achieved by flushing the seal chamber with liquid to take away heat and control the temperature rise.

2. Lower the liquid temperature. In some cases, the liquid temperature is too high to affect the sealing performance. In such cases, the temperature must be reduced to improve the performance of the liquid.

3. Change the pressure of the seal chamber. In some cases, the seal chamber pressure needs to be increased or decreased to improve performance. This can be achieved by inhibiting evaporation or reducing the heat load on the seals.

4. Clean process fluid. If the process fluid contains unsuitable solid particles or contaminants, the fluid in the seal cavity needs to be cleaned. In extreme cases, it may also be necessary to provide clean fluid from outside the sealing system.

5. Control the atmospheric side of the seal. Process liquids may dry, crystallize, or coke as they come into contact with the atmosphere. It is very important to prevent interaction with the atmosphere so as not to adversely affect the sealing performance.

Classification of mechanical seal flushing schemes

◆ Single Seals

PLAN 01 (Single end self flushing)

PLAN 02 (jacket cooling and heat tracing)

PLAN 11 (self flushing)

PLAN 13 (back flushing)

PLAN 14 (forward+reverse flushing)

PLAN 21 (self flushing with cooling)

PLAN 23 (internal flushing with circulating sleeve)

PLAN 31 (self flushing with suspension separator)

PLAN 32 (external flushing)

PLAN 41 (self flushing with suspension separator and heat exchanger)

◆ Dual Seals

PLAN 52 (series seal with non pressure buffer tank)

PLAN 53A (double face seal with pressure sealing fluid)

PLAN 53B (double face seal of forced circulation sealing fluid)

PLAN 53C (double face seal with booster tank)

PLAN 54 (double face seal with external sealing fluid)

◆ Quench Seals

PLAN 62 (external flushing or quenching to prevent solid particles from accumulating on the sealing surface)

PLAN 65 (with float level switch to measure seal leakage)

◆ Gas Seals

PLAN 72 (using isolated nitrogen for series dry gas seal of volatile medium)

PLAN 74 (double face dry gas seal)

PLAN 75 (for series dry gas seal of non-volatile medium)

PLAN 76 (series dry gas seal with external sealing gas)