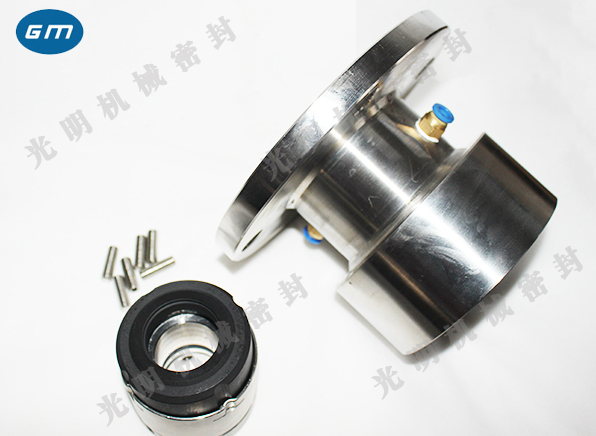

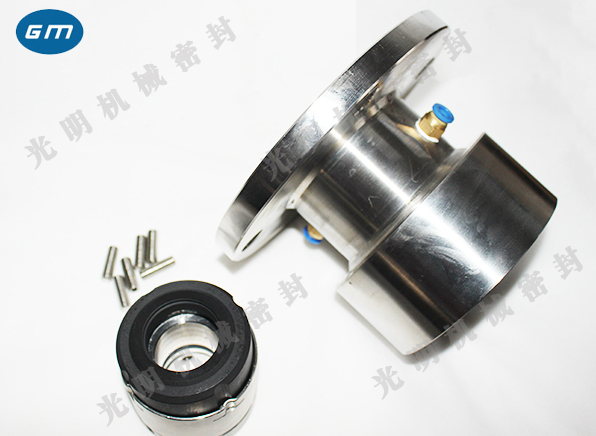

Mechanical seal for kettle instructions

1. Mechanical seal (end face seal) is a device to prevent fluid leakage, which is composed of at least one pair of end faces perpendicular to the rotation axis, under the action of fluid pressure, elastic force of compensation mechanism and the cooperation of auxiliary seals, to keep sticking and relative sliding.

2. Mechanical seal for kettle is applicable to various steel kettle, enamel kettle, glass lined kettle mixing shaft and similar vertical rotating shaft seals.

3. Mechanical seal is a kind of precision device. Its sealing performance and service life largely depend on the installation accuracy of mechanical seal and the operating conditions of mixing equipment using mechanical seal. Practice has proved that before installing the mechanical seal, the accuracy of the flange end face of the vessel where the mechanical seal is installed and the diameter of the mixing shaft should be inspected and carefully installed, which is an effective way to avoid premature failure of the seal and extend its service life.

Installation of mechanical seal for kettle

1. Relevant requirements before installation

(1) The double end mechanical seal shall be subject to static pressure test before installation. The test pressure may not meet the specified requirements, which is mainly an inspection test to prevent damage to internal parts during transportation and handling.

(2) The mixing shaft (or transmission shaft) installed at the mechanical seal shall meet the requirements

(3) When the radial runout tolerance fails to meet the requirements, it shall be considered to add intermediate bearing or bottom bearing in the kettle, or select mechanical seal with built-in bearing.

(4) . The end of the mixing shaft diameter where the auxiliary seal is installed shall be chamfered as shown in Figure 1, and the shaft diameter surface shall not be scratched to prevent the seal ring from being scratched.

(5) The two sides of the cauldron flange (or bottom cover) mounting rack and mechanical seal shall be parallel, and the parallelism shall not be greater than 0.05mm. Height H can be measured on the circumference and calculated by the maximum and minimum values.

(6) The interface plane of cauldron flange (or bottom cover installation) is the datum plane for installing mechanical seal. This plane must be clean, smooth and flat without dirt and uneven concave and convex defects. It should be perpendicular to the axis line of the transmission device (i.e. the axis line of the rack), or it will affect the sealing performance of the mechanical seal and cause leakage. The perpendicularity of this plane and the axis should not be greater than 0.10 mm; The mechanical seal for the autoclave shall not be greater than 0.05mm.

(7) Check whether the flange of kettle mouth is consistent with the relevant dimensions of mechanical seal installation. Note: During installation, the position of each pipeline interface and the rack shall be placed correctly.

(8) Before installation, the parts shall be cleaned, especially the joint surfaces. The moving ring and the stationary ring shall be protected, especially the sealing surface, to prevent collision and scratch.

(9) The sealing fluid system (i.e. circulating protection system) shall be carefully cleaned. The sealing fluid shall be free of solid impurities such as dirt and rust, which are one of the important reasons for seal leakage and affecting seal life.

(10) Under the working condition of strong solvent or high temperature, the O-ring on the bottom plane of mechanical seal should be changed to F4 flat gasket.