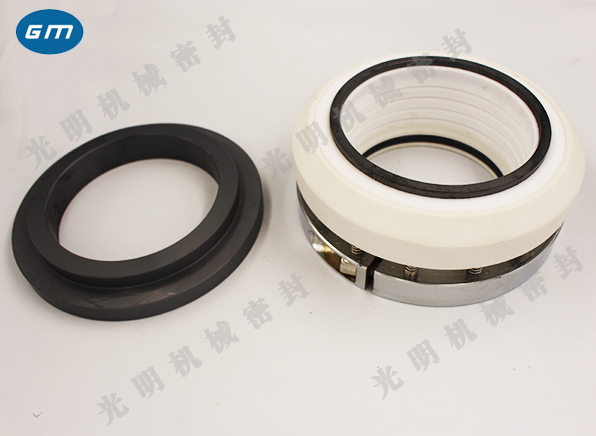

The working principle of mechanical seal 204 Mechanical seal manufacturer Tell you!

Mechanical seal is a shaft seal device that can prevent leakage by a pair or several pairs of end faces that slide relative to the shaft under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and are matched with auxiliary seals.

Selection of Common Materials for Mechanical Seals

Purified water; normal atmospheric temperature; (Dynamic) 9CR18, 1CR13 surfacing cobalt chromium tungsten, cast iron; (Static) resin impregnated graphite, bronze, phenolic plastic.

River water (including sediment); normal atmospheric temperature; Tungsten carbide

Seawater; normal atmospheric temperature; (Dynamic) tungsten carbide, 1CR13 surfacing cobalt chromium tungsten, cast iron; (Static) resin impregnated graphite, tungsten carbide, cermet;

Superheated water 100 ℃; (Dynamic) tungsten carbide, 1CR13 surfacing cobalt chromium tungsten, cast iron; (Static) resin impregnated graphite, tungsten carbide, cermet;

Gasoline, lubricating oil, liquid hydrocarbon; normal atmospheric temperature; (Dynamic) tungsten carbide, 1CR13 surfacing cobalt chromium tungsten, cast iron; (Static) impregnated resin or tin antimony alloy graphite, phenolic plastic.

Gasoline, lubricating oil, liquid hydrocarbon; 100 degrees; (Dynamic) tungsten carbide, 1CR13 surfacing cobalt chromium tungsten; (Static) impregnated with bronze or resin graphite.

Gasoline, lubricating oil, liquid hydrocarbon; Containing particles; Tungsten carbide; Tungsten carbide (static).

3. Types and uses of sealing materials

The sealing material shall meet the requirements of sealing function. Because the sealed medium is different and the working premise of the equipment is different, the sealing materials are required to have different adaptability. The requirements for sealing materials are generally:

1) The material has good compactness and is not easy to leak media;

2) Have appropriate mechanical strength and hardness;

3) Good compressibility and resilience, small permanent deformation;

4) No softening and decomposition under high temperature, no hardening and no embrittlement under low temperature;

5) It has good corrosion resistance, and can work in acid, alkali, oil and other media for a long time. Its volume and hardness change little, and it does not adhere to the metal surface;

6) Small friction coefficient, good wear resistance;

7) It has the flexibility of combining with the sealing surface;

8) Good aging resistance and durability;

9) Processing and manufacturing are convenient, the price is cheap, and the materials are easy to obtain.

Rubber is the most commonly used sealing material. In addition to rubber, graphite, polytetrafluoroethylene and various sealants are also suitable for sealing materials.

4. Technical essentials of mechanical seal installation and use

1) The radial runout of the equipment shaft should be ≤ 0.04mm, and the axial runout should not be greater than 0.1mm;

2) The sealing parts of the equipment shall be kept clean during installation, the sealing parts shall be cleaned, and the sealing face shall be intact to prevent impurities and dust from entering the sealing parts;

3) During installation, it is strictly prohibited to bump or knock, so as not to damage the friction pair of mechanical seal and cause seal failure;

4) During installation, a layer of clean mechanical oil shall be coated on the surface in contact with the seal to facilitate smooth installation;

5) When installing the stationary ring gland, the screws must be tightened evenly to ensure the perpendicularity between the end face of the stationary ring and the axis line;

6) . After installation, the moving ring can be moved flexibly on the shaft with a certain elasticity by pushing it manually;

7) After installation, rotate the shaft by hand, and the shaft should have no sense of weight;

8) . The equipment must be filled with media before operation to prevent the seal failure caused by dry friction;

9) For crystallizable and granular media, corresponding flushing, filtering and cooling measures should be taken when the medium temperature is 80OC. For various auxiliary devices, please refer to the relevant dimensions of mechanical seal.

10) During installation, a layer of clean mechanical oil shall be coated on the surface in contact with the seal. Special attention shall be paid to the selection of mechanical oil for different auxiliary seal materials to avoid oil invasion, expansion or accelerated aging of O-ring, which may lead to premature failure of the seal.