Mechanical seal manufacturer Introduce the sealing mechanism

If you want to learn sealing, you must first understand the leakage. If you understand the principle of leakage, then the corresponding sealing mechanism will also be available. There are three kinds of leakage——

One is leakage, that is, leakage between sealing surface gaps

The other is leakage, that is, leakage of sealed fluid through capillary tube of seal material

The third is diffusion, which refers to the material transfer of sealing medium through gaps or capillary tubes of materials under the effect of concentration difference.

About sealing method

There are several sealing methods——

1. Minimize the parts with seals

2. Blocking and isolation

3. Lead out or injection

4. Increase leakage resistance

5. Add power element in the channel

6. Combination of multiple sealing methods

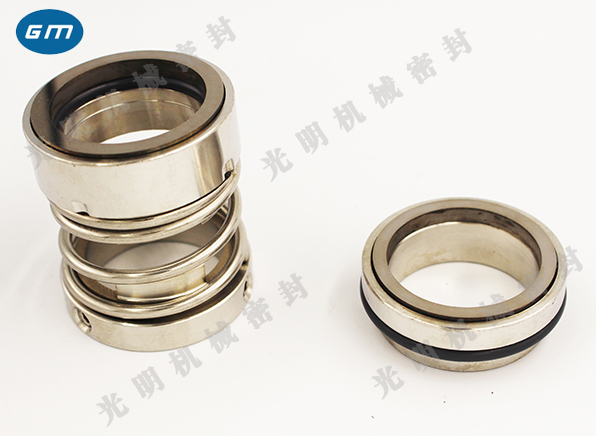

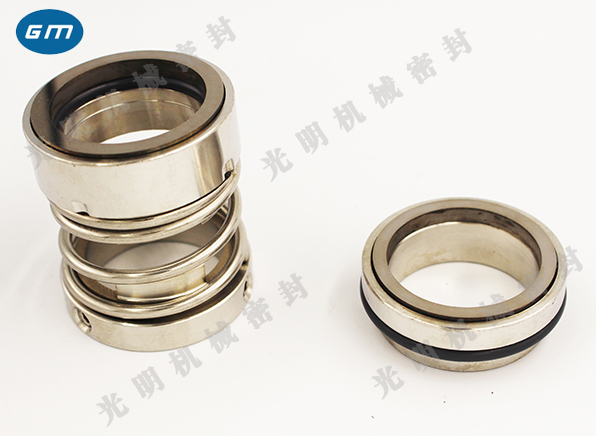

Common sealing forms

Gasket seal, packing seal, mechanical seal, non-contact seal and injection type leak stoppage under pressure are common sealing forms. Among them, packing seal is the most common, which also includes soft packing seal, hard packing seal and shaped packing seal. Formed packing seal includes our common O-ring, Y-ring, oil seal, etc. The non-contact seal includes clearance seal, labyrinth seal, floating seal, dynamic seal, magnetic fluid seal and totally enclosed seal.

Common gasket performance --- new materials and new technology

1) Common gasket performance

When using the valve, the original gasket is often replaced according to the specific situation. Common gaskets include: rubber flat washer, rubber O-ring, plastic flat washer, PTFE wrapped washer, asbestos rubber washer, metal flat washer, metal profiled washer, metal sheath washer, corrugated washer, spiral wound washer, etc.

(1) Rubber flat washer: easy to deform, easy to compress, but poor pressure and temperature resistance. It is only used in places with low pressure and low temperature. Natural rubber has certain acid and alkali resistance, and the use temperature should not exceed 60 ℃; Neoprene can also resist certain acids and alkalis, and the operating temperature is 80 ℃; Buna-N rubber is oil resistant and can be used up to 80 ℃; Fluorine rubber has good corrosion resistance and temperature resistance, and can be used in 150 ℃ medium.

(2) Rubber O-ring washer: the section shape is round, which has a certain self tightening effect. The sealing effect is better than that of flat washer, and the compression force is smaller.

(3) Plastic flat washer: The biggest feature of plastic is its good corrosion resistance, while most plastics have poor temperature resistance. Polytetrafluoroethylene (PTFE) is the best plastic. It not only has excellent corrosion resistance, but also has a wide temperature resistance range. It can be used for a long time within - 180 ℃~+200 ℃.

(4) PTFE wrapped gasket: in order to give full play to the advantages of PTFE and make up for its poor elasticity, PTFE wrapped rubber or asbestos rubber gaskets are made. In this way, it not only has the same corrosion resistance as the PTFE flat washer, but also has good elasticity, enhancing the sealing effect and reducing the compression force. The section shape is shown in Figure 4-20.

(5) Asbestos rubber gasket: cut from asbestos rubber sheet. Its components are 60-80% asbestos and 10-20% rubber, as well as fillers and vulcanizing agents. It has good heat resistance, cold resistance, chemical stability, and is rich in supply and cheap. When in use, the pressing force need not be great. Since it can adhere to metal, it is better to coat the surface with a layer of graphite powder to avoid the difficulty of disassembly.

Asbestos rubber sheet has four colors: gray, used for low pressure (grade XB-200, pressure resistance ≤ 16kg/cm2, temperature resistance 200 ℃); Red, for medium pressure (XB-350, pressure resistance up to 40 kg/cm2, temperature resistance 350 ℃); Purplish red, used for high pressure (grade XB-450, pressure resistance 100 kg/cm2, temperature resistance 450 ℃); Green, used for oil, with good pressure resistance.

(6) Metal flat heating ring: lead, temperature resistance 100 ℃; Aluminium 430 ℃; Copper 315 ℃; Low carbon steel 550 ℃; Silver 650 ℃; Nickel 810 ℃; Monel (nickel copper) alloy 810 ℃, stainless steel 870 ℃. Among them, lead has poor pressure resistance, aluminum can withstand 64kg/cm2, and other materials can withstand high pressure.

(7) Metal anisotropic washer:

Lens washer: self tightening, used for high-pressure valves.

Oval washer: also belongs to high-pressure self tightening washer.

Conical double washer: used for high-pressure internal self tightening seal.

In addition, there are square, diamond, triangle, tooth, swallow tail, B, C, etc., which are generally only used in high and intermediate pressure valves.

(8) Metal sheath washer: metal has good temperature resistance and pressure resistance, and good elasticity. The foreskin materials include aluminum, copper, low carbon steel, stainless steel, Monel alloy, etc. The filling materials include asbestos, polytetrafluoroethylene, glass fiber, etc.

(9) Corrugated washer: It has the characteristics of small compression force and good sealing effect. The combination of metal and nonmetal is often used.

(10) Spiral wound gasket: it is a kind of thin metal belt and non-metallic belt that are tightly tied together and wound into a multi-layer circle with wavy cross section, which has good elasticity and sealing performance. The metal belt can be made of 08 steel, 0Cr13, 1Cr13, 2Cr13, 1Cr18Ni9Ti, copper, aluminum, titanium, Monel alloy, etc. Non metallic belt materials include asbestos, polytetrafluoroethylene, etc.

Above, some figures are listed when describing the performance of sealing washer. It must be noted that these figures are closely related to the flange form, medium condition, installation and repair technology, and sometimes can be exceeded, sometimes cannot be reached. Moreover, the pressure resistance and temperature resistance are also mutually transformative. For example, when the temperature is high, the pressure resistance is often reduced. These subtle problems can only be understood in practice.