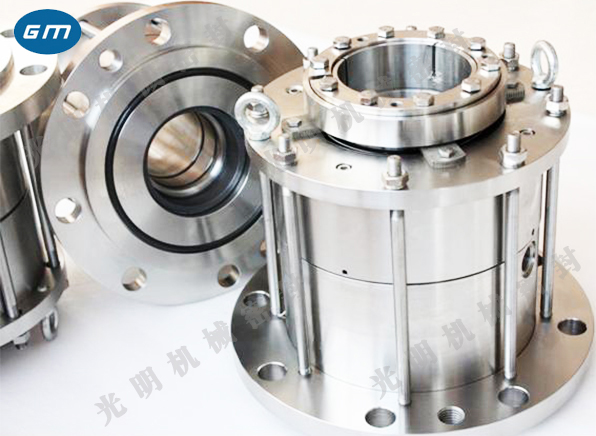

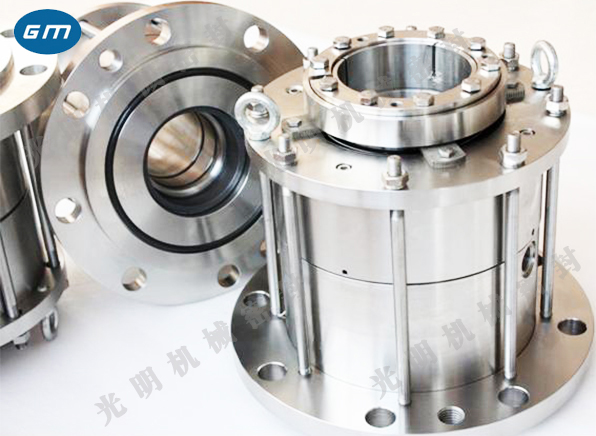

introduce Mechanical seal for kettle And how to deal with the problem correctly in case of failure.

The kettle mechanical seals are divided into the following six types: 201 type single end face single spring unbalanced seal, 202 type single end face multi spring unbalanced seal, 203 type single end face single spring balanced seal, 204 type single end face multi spring balanced seal, 205 type double end face multi spring unbalanced seal, and 206 type double end face multi spring balanced seal.

Common faults and solutions of mechanical seal for kettle

1. Fault phenomenon: leakage occurs at the sealing surface.

Fault cause: screw thread is loose; The sealing surface is damaged.

Troubleshooting: Retighten the screw; Regrind and polish the sealing surface.

2. Fault phenomenon: there is leakage at the valve.

Fault cause: the valve rod (needle) and valve port sealing surface are damaged.

Troubleshooting: repair and replace the valve rod (needle) and valve port.

3. Fault phenomenon: the external magnetic steel rotates, the internal magnetic steel does not rotate, and the motor current decreases.

Cause of fault: the temperature rise in the kettle is too high, the cooling cycle is not smooth, and the internal magnetic steel is demagnetized due to high temperature. During hydrogenation reaction, the inner magnetic steel sleeve was cracked and the inner magnetic steel expanded.

Troubleshooting: inform the supplier to replace the inner magnetic steel.

4. Fault phenomenon: There is friction noise in the magnetic coupling driver.

Cause of fault: the shaft sleeve and bearing are worn, the clearance is too large, and the internal magnetic steel rotates and jumps.

Troubleshooting: contact the supplier or Mechanical seal manufacturer Contact and replace the bearing and shaft sleeve.