204 Mechanical seal Introduction to basic knowledge

Mechanical seal (end face seal) is a device used to solve the sealing between rotating shaft and engine body. It is a device to prevent fluid leakage, which is composed of at least one pair of fluid pressure at the end face perpendicular to the rotating axis and the elastic force (or magnetic force) of the compensation mechanism, and the auxiliary seal, which is kept in contact with each other and slides relatively. It is commonly used in rotary fluid machinery such as pumps, compressors, reaction agitators, and also used for sealing gear boxes, ship stern shafts, and so on. Therefore, mechanical seal is a universal shaft seal device.

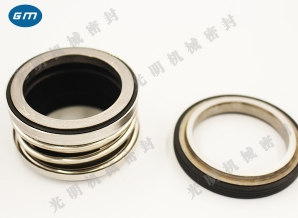

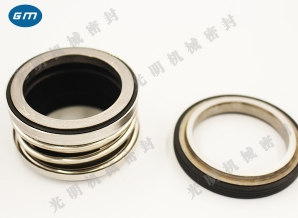

Mechanical seal structures are various, and the commonly used mechanical seal structure is face seal. The static ring and dynamic ring of the end face seal form a pair of friction pairs, whose function is to prevent medium leakage. It requires that the static ring and the dynamic ring have good wear resistance. The dynamic ring can move flexibly in the axial direction, automatically compensate the wear of the sealing surface, and make it fit well with the static ring; The static ring is floating and plays a buffer role.

Therefore, the sealing surface shall have good processing quality to ensure that the sealing pair has good bonding performance. The basic elements of mechanical seal include static ring, dynamic ring, gland, push ring, spring, locating ring, shaft sleeve, dynamic ring seal ring, static ring seal ring, shaft sleeve seal ring, etc.

Elastic elements (springs, bellows) mainly play the role of pre tightening, compensation and buffering. It is required to always maintain sufficient elasticity to overcome the friction of auxiliary seals and transmission parts and inertia of moving rings, so as to ensure good fit of end seal pairs and tracking of moving rings. Materials are required to be corrosion resistant and fatigue resistant.

The auxiliary seal (O-ring, V-ring, U-ring, wedge ring and special-shaped ring, etc.) mainly serves as the seal of stationary ring and dynamic ring, and also plays the role of floating and buffering. It is required that the sealing elements of the static ring can ensure the tightness between the static ring and the gland, the static ring has a certain floatability, and the sealing elements of the dynamic ring can ensure the tightness between the dynamic ring and the shaft or shaft sleeve, and the floatability of the dynamic ring. Materials shall be heat-resistant.