stir Mechanical seal for kettle Difference from pump mechanical seal?

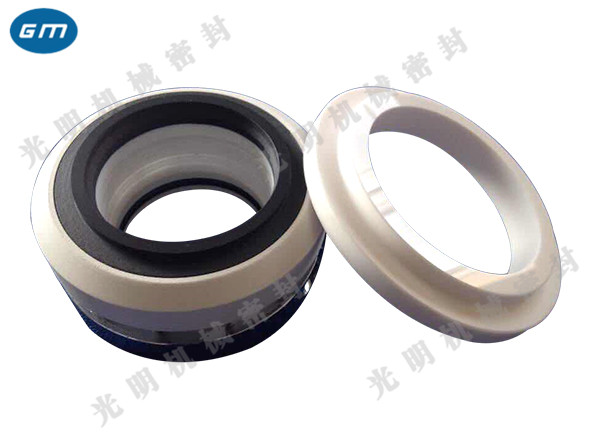

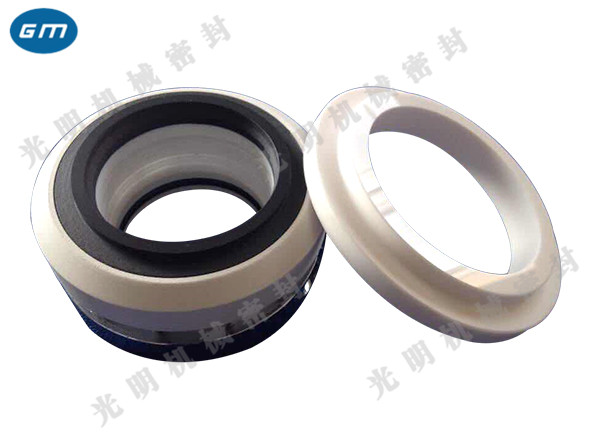

Mechanical seal for agitator kettle and mechanical seal for pump are mechanical parts used to seal rotating shaft and static pump chamber. The sealed part is a cylindrical area, the shaft in the equipment rotates and penetrates inside and outside the equipment, and the body part is still and full of fluid medium inside. Driven by pressure difference, concentration difference and temperature difference, fluids inside and outside the equipment exchange with each other; "Sealing" means to control the fluid exchange between internal and external areas, so that there is "no leakage" at the interface. Bucht explained in his book Industrial Sealing Technology that mechanical seal is a combined mechanism composed of a series of simple design elements, and the sealing function is completed by two main sealing rings with planes to prevent leakage. One seal ring rotates together with the shaft, and the other seal ring is fixed on the housing. In order to seal the centrifugal pump shaft, the static seal ring is installed on the gland of the seal chamber. During the rotation of the pump shaft, the sealing surface of the sealing ring installed on the shaft rubs against the opposite static ring sealing surface. The contact between these two sealing contact surfaces acts like a bearing and is subject to wear. Any form of system leakage must pass through this sealing contact surface. The axial force keeps the seal ring in frictional contact all the time. Its source can be mechanical or hydraulic. In many designs, the sum of the two is taken. This stable contact can prevent leakage from friction surfaces or minimize leakage.