The utility model relates to the technical field of mechanical sealing devices, in particular to a dry running Mechanical seal for kettle 。

Background technology:

Kettle mechanical seal is an ideal way to solve the problem of mixing shaft seal. According to the number of sealing faces, there are single end mechanical seal and double end mechanical seal. The double end mechanical seal is generally equipped with a balanced circulation system, which can be used in occasions with more stringent requirements for the seal, such as flammable, explosive, toxic, corrosive, and high vacuum. The sealing structure is an external flushing structure, The flushing fluid can be clean water or industrial recycled water. The pressure of the flushing fluid is lower than the pressure of the seal chamber. The flushing fluid is input at the upper end of the auxiliary sleeve and output at the lower end of the auxiliary sleeve. The seal plays the role of cooling and flushing. The auxiliary devices of the mechanical seal include temperature regulator, balance tank (isolation fluid container), forced circulation balance system, etc.

The structure of the mechanical seal device on the market is not new and flexible enough. The general mechanical seal device usually uses water injection to cool the shaft to a certain extent, which can easily cause leakage in the process of water injection. At the same time, when sealing the shaft, the general mechanical seal device may cause some wear on the shaft surface. Therefore, We propose a mechanical seal for dry running kettle.

Technical implementation elements:

The purpose of the utility model is to provide a mechanical seal for a dry running kettle, so as to solve the problem that the structure of the mechanical seal device proposed in the above background technology is not novel and flexible enough. The general mechanical seal device usually cools the rotating shaft by water injection, which can easily cause leakage in the process of water injection, At the same time, when sealing the shaft, the general mechanical seal device may cause some wear on the shaft surface.

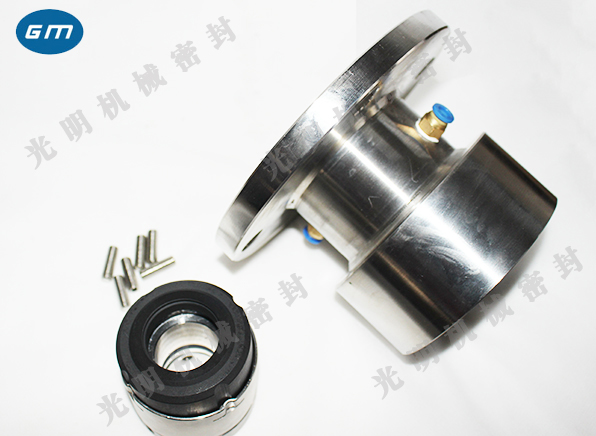

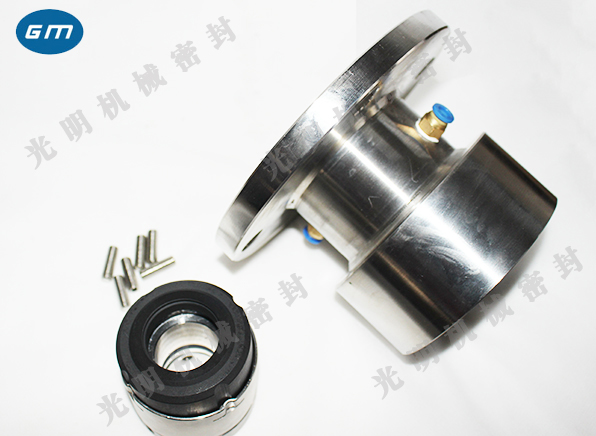

To achieve the above purpose, the utility model provides the following technical scheme: a mechanical seal for a dry running kettle, which comprises a rotating shaft body, a fixing screw rod and a connecting rod. The inner side of the rotating shaft body is inlaid with a support column, and the outer side of the rotating shaft body is connected with a protective shell. The upper end of the outer side of the protective shell is fixed with a spring fixing base, In addition, the middle and lower ends of the spring fixed base are connected with springs, the fixed screw rod is arranged at the outer left end of the spring fixed base, and the right end of the fixed screw rod is connected with the spring, the bottom end of the spring is installed with a movable ring fixed base, and the movable ring fixed base is connected with the spring through a connection snap, and the lower end of the movable ring fixed base is installed with a movable ring, The inner wall of the dynamic ring is fixed with a dynamic ring seal ring, the connecting rod is arranged at the bottom of the dynamic ring, and the lower side of the connecting rod is installed with a static ring, The inner side of the cooling card slot is inlaid with a cooling plate, and the lower end of the outer side of the cooling card slot is fixed with a translational baffle plate. The right end of the translational baffle plate is arranged with a translational bearing, and the left end of the translational baffle plate is provided with a connecting nut. The outer wall of the protective shell is installed with a friction partition layer, and the protective shell is connected with the main body of the rotating shaft through a mosaic pillar.

Preferably, the rotating shaft main body and the support column are integrated, and a semi enclosed structure is formed between the rotating shaft main body and the protective shell.

Preferably, the connection mode of the spring fixing base and the spring is threaded connection, and the spring is arranged in a rectangular structure with a group, and the spring is symmetrically arranged with the vertical central axis of the rotating shaft main body as the symmetry axis.

Preferably, the connection mode between the movable ring fixing base and the spring is snap connection, and the transverse diameter of the movable ring fixing base is equal to 1.5 times of the transverse diameter of the movable ring.

Preferably, the connection mode between the moving ring and the moving ring seal ring is bonding, and the moving ring seal ring and the stationary ring seal ring are mutually parallel.

Preferably, the cooling clamping groove penetrates through the inner middle end of the stationary ring, and the connection mode of the cooling clamping groove and the cooling plate is clamping groove connection.

Compared with the prior art, the beneficial effect of the utility model is that the mechanical seal for the dry running kettle is provided with a protective shell, which can insulate and protect the main body of the rotating shaft to a certain extent, prevent the damage of the external environment to the main body of the rotating shaft, and make the main body of the rotating shaft more stable during operation. The connection mode between the spring fixed base and the spring is threaded connection, The spring fixed base can facilitate the installation of the spring by the staff. Under the setting of the moving ring and the static ring, the device can seal the main body of the rotating shaft strictly, and prevent the separation of the main body of the rotating shaft from the device when the main body of the rotating shaft is working. Under the setting of the friction barrier, the friction between the device and the main body of the rotating shaft can be improved, The connection between the device and the main body of the rotating shaft is more firm. Under the setting of the dynamic ring seal ring and the static ring seal ring, the overall sealing performance of the device can be improved, so that the main body of the rotating shaft can process machinery easily, and the utilization rate of the device can be improved. Under the setting of the cooling slot and the cooling plate, the device can have a certain cooling effect, It is convenient to improve the strength and toughness of the main shaft.