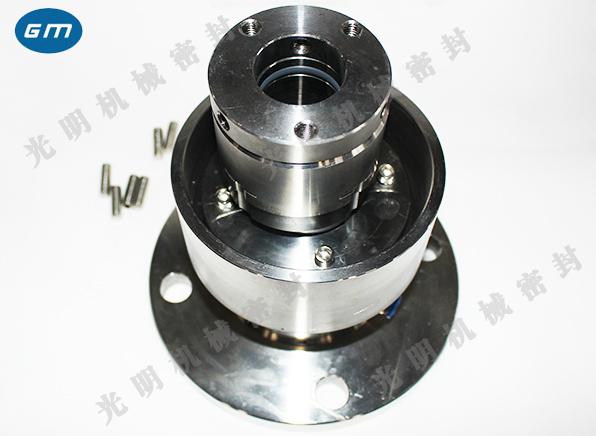

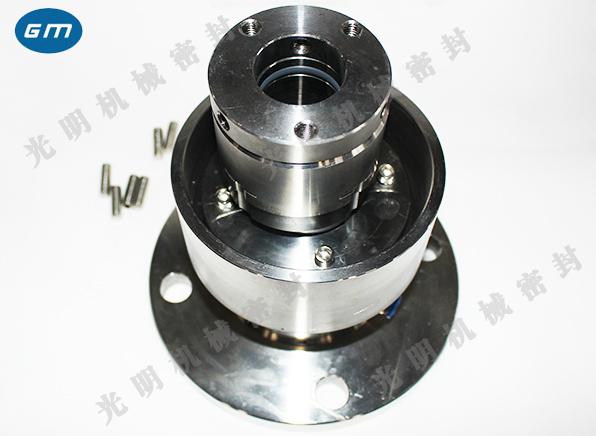

Mechanical seal for kettle High sealing requirements

The mechanical seal for kettle has high sealing requirements. When the shaft needs to bear large radial force, the mechanical seal with built-in bearing should be selected, but it is generally not used as the bearing point of the shaft. If it is necessary to use this as the supporting point, the improved mechanical seal with T after the model shall be selected.

The built-in bearing of the kettle mechanical seal is changed into two tapered roller bearings, which can replace the supporting bearing chamber of the rack (which can be used as a force bearing point of the mixing shaft in the rack). The mechanical seal for kettle can be made into an integral shaft structure to facilitate installation and maintenance and improve the stiffness of the support. Other working conditions are the same as the corresponding 205, 206 and 207 mechanical seals.

The latest development of kettle mechanical seal technology Mechanical seal is a device used to solve the sealing between the rotating shaft and the body. The mechanical seal for kettle is a device to prevent fluid leakage, which is composed of at least one pair of end faces perpendicular to the rotation axis, under the action of fluid pressure, elastic force (or magnetic force) of compensation mechanism and the cooperation of auxiliary seal, and is commonly used in rotary fluid machinery such as pumps and compressors.

The device is composed of at least one pair of end faces perpendicular to the rotation axis, which are kept stuck and relatively sliding under the cooperation of fluid pressure, elastic force (or magnetic force) of compensation mechanism and auxiliary seal to prevent fluid leakage. Since the transmission shaft runs through the inside and outside of the equipment, there is a circumferential gap between the shaft and the equipment through which the medium in the equipment leaks outward. If the pressure in the equipment is lower than the atmospheric pressure, the air leaks into the equipment. Therefore, there must be a shaft sealing device to prevent leakage.