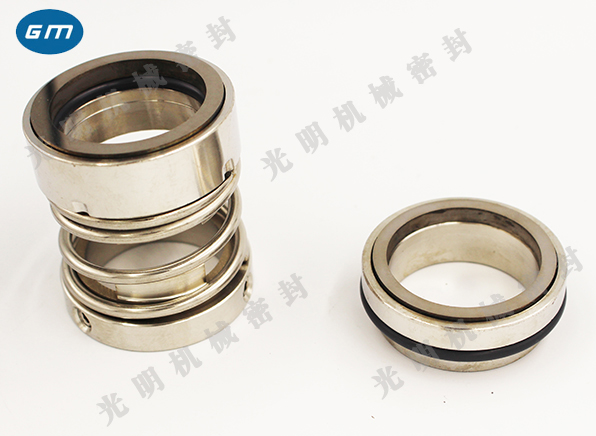

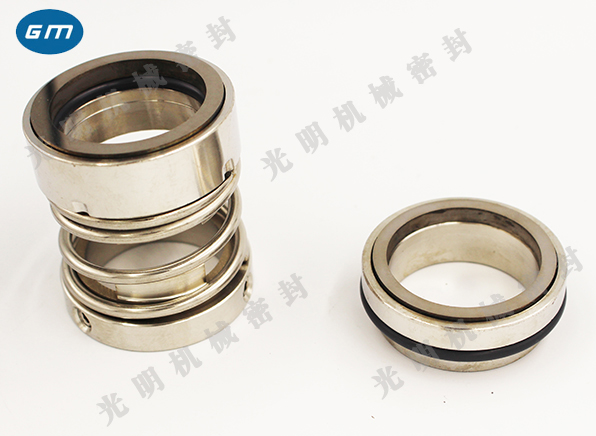

Mechanical seal manufacturer Explanation of model selection

According to different working conditions and medium properties, mechanical seals include high-temperature and low-temperature resistant mechanical seals, high-pressure and corrosion resistant mechanical seals, particle resistant mechanical seals, and mechanical seals suitable for light hydrocarbon media that are easy to vaporize. Mechanical seals with different structures and materials shall be selected according to different uses. Mechanical seals are widely used in various enterprises. Such as water pump plants, printing and dyeing machinery plants, paper mills, power plants, chemical plants, pharmaceutical shipyards, and sewage treatment plants, which are widely used in hospitals, agriculture, equipment cooling, tanning industry, heavy machinery, etc.

The main parameters of model selection include: pressure of sealing chamber (MPa), fluid temperature (℃), working speed (m/s), fluid characteristics and effective space for installing seals.

The basic principles of model selection are:

1. According to the pressure of the sealing chamber, determine whether the sealing structure is balanced or unbalanced, single end or double end.

2. According to the working speed, the rotary type or static type, hydrodynamic type or non-contact type shall be adopted.

3. According to the temperature and fluid properties, determine the friction pairs and auxiliary sealing materials, and correctly select the lubrication, flushing, insulation, cooling and other mechanical seal cycle protection systems.

4. Multiple springs or single springs or Wave spring , internal or external.